Chapter 1, the core significance and challenges of bulk purchasing smart locator tags

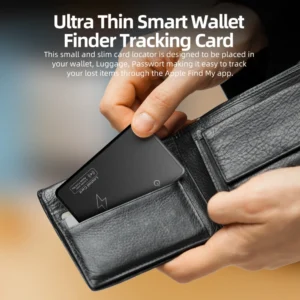

Under the background of the popularization of Internet of things technology, smart locator tags have been widely used in many scenarios: consumer end covers pet anti-lost, personal baggage tracking; The enterprise end involves logistics asset management (container and pallet tracking) and industrial equipment monitoring Special industries include medical equipment monitoring, cold chain logistics tracking, personnel safety monitoring (elderly, field personnel positioning) . Buying these products in bulk not only reduces unit costs through economies of scale, but also ensures continuity of operations such as logistics distribution and work safety-but there are three central challenges in the current market:

Product homogeneity is serious: positioning accuracy, endurance, environmental adaptability and other core performance is uneven;

Supplier qualification confusion: after-sales no guarantee;

Demand mismatch risk: Enterprises do not define their own scene requirements (such as indoor/outdoor positioning, waterproof grade, ecological compatibility-RRB- , resulting in the purchase of products can not be used.

Therefore, “Finding reliable suppliers” is the key to the success of bulk purchasing, need to establish the whole process control system from“Demand definition” to“Long-term cooperation”.

Chapter 2, before purchasing: Identify your core requirements for bulk purchasing

A prerequisite for sound sourcing is a“Soul mate”-the ability to accurately screen suppliers with clearly defined requirements. The list of requirements should be organized in five dimensions:

2.1 product performance requirements (core indicators)

| The demand dimension | Examples of key parameters | Scenario adaptation instructions |

| Product type | Bluetooth tags (AIRTAG class) , GPS locators, multi-mode devices (Bluetooth + GPS + NB-IOT) | Bluetooth tags for personal belongings, GPS locators for logistics fleet management, and multi-mode devices for wide area asset tracking |

| Positioning accuracy | Outdoor ≤1 m (GPS/Beidou) , indoor ≤3 m (UWB) | Logistics warehouse needs high precision indoor, outdoor transportation needs GPS stability |

| Endurance | Battery life ≥6 months (bluetooth tags) , ≥2 years (NB-IoT) | Static assets (e.g. , shelf life) require long battery life, dynamic assets accept high-frequency charging |

| Means of communication | Bluetooth, NB-IoT, Lora, UWB | UWB for closed environments (basements) and NB-IoT for wide-area tracking |

| Environmental Adaptability | Waterproof grade (IP65/IP67/IP68) , operating temperature (-30 °C ~ 60 °C) | IP65 for daily outdoor use, IP68 for wading scenarios, and low temperature resistance for cold chain scenarios |

| Eco-compatibility | Support for Apple Find My, Google Find My Device, Samsung SmartThings | For apple users, Find My is required; for Android users, the Google Ecosystem is required |

| Additional features | Alarm function (low power/disassembly alarm) , data encryption | Classified scenarios (such as military assets) require strong encryption |

2.2 procurement size and cycle requirements

Clear batch quantity: such as the first purchase of 500 trial production, follow-up monthly stable purchase of 2000, suppliers need to match the corresponding capacity;

Lead Time: if the goods will arrive within 30 days before the peak season, the supplier’s emergency production capacity should be confirmed

Replenishment mechanism: whether to establish safety stock, whether the supplier can support emergency replenishment within 72 hours;

Minimum order quantity (MOQ) : verify that the supplier’s minimum purchase quantity is in line with their own budget and sales plan (e. g. cross-border e-commerce small-batch trial needs MOQ ≤500 units) .

2.3 cost and budget requirements

Clear unit cost cap: avoid only look at the“Unit price”, need to calculate the total cost (including freight, installation and commissioning fees, after-sales maintenance fees, tariffs < export scenario >) ;

Graded Price Expectation: confirm purchasing quantity step discount (e. g. 1000 pieces unit price, 5000 pieces unit price, 10000 pieces unit price difference) ;

2.4 compliance and certification requirements

Regional Certification: CE certification for export to Europe, FCC certification for export to the United States, UKCA certification for UK, CCC certification for domestic sales;

Industry special certification: Medical Scenarios need FDA certification, explosion-proof scenarios need Ex certification;

Eco-certification: Apple Needs Apple MFI certification, Android needs Google Find My Device compatibility certification;

2.5 technical support and after-sales requirements

System docking: whether the supplier needs to provide API interface, and enterprise ERP/WMS system or personal APP through;

Ability to customize: whether to support LOGO printing, shell color customization, APP UI customization (such as corporate customers need to brand display) ;

After-sales response: Repair Cycle, technical support, firmware update service (long-term performance optimization needs) ;

Chapter 3,6 core channels for selecting reliable suppliers

Once the demand is identified, expand supplier resources through multiple channels to avoid selection limitations caused by a single channel, and cross-validate supplier credibility:

3.1 industry vertical platform (high accuracy)

Internet of things professional platform: such as the Internet of Things World, China’s Internet of Things Industry Application Alliance, the platform into the supplier is mostly the original factory, and after qualification audit;

Enterprise Procurement Platform:

Domestic: Alibaba enterprise purchase (filter“Strength merchants”“Deep factory audit” label, view transaction records and customer reviews) , jd.com enterprise purchase (priority to choose“Self-employed suppliers”) ;

International: Alibaba international site (screen“Gold Supplier”, “Verified Supplier”, prefer factories with“Onsite Check” logo) , Global Sources (prefer export suppliers, experienced in foreign trade) , Made-in-China (suitable for looking for original manufacturers in sub-categories) .

3.2 trade shows and summits (field trips)

Highlights:

International: CES Consumer Electronics Show, Munich, Germany (CEBIT) ;

Domestic: China International Internet of Things Expo (CIOT) , Shanghai International Intelligent Hardware Exhibition, Shenzhen International Logistics and Supply Chain Expo, Hong Kong Electronics Show (HKTDC) ;

Exhibition value: on-site view of product samples, test performance (such as positioning accuracy, waterproof) , and the supplier responsible for face-to-face communication production scale, custom capacity;

3.3 peer recommendations and industry associations (high credibility)

Peer research: to consult with the leading enterprises in the same industry to understand the experience of cooperation (such as delivery on time, after-sales response speed) ;

Association endorsement: Join the local Internet of Things Association, the logistics and Supply Chain Association, and the consumer electronics association, and obtain a“Quality supplier directory” recommended by the Association. Such suppliers are usually accredited by the association.

3.4 official channels of cooperation (ecological adaptation needs)

If you need to connect with the Apple ecosystem: Screen Partner factories through Apple’s official MFI authorization list (make sure the products support Find My network to avoid infringement risks) ;

To adapt to the Android ecosystem: Check Google Find My Device’s official list of compatible partners, or Find suppliers through Samsung’s SmartThings developer platform

Advantages: official channel suppliers are subject to the ecological side of the qualification audit, product compatibility and compliance more guaranteed.

3.5 active research (deep mining)

Factory official website inquiry: verify the registered capital of suppliers, established time;

Industry chain upstream traceability: contact the core components of the locator manufacturer

Social media research: check out LinkedIn to see what vendors are up to and determine how active and active they are.

3.6 third-party services (risk management)

Purchasing agent: If you need to enter unfamiliar markets (such as Southeast Asia, Europe) , you can entrust local purchasing agents for factory audit, Order Monitoring, customs clearance services to reduce cross-border procurement risk;

Cooperate with Quality Inspection Agency: cooperate with SGS, Intertek and other third party quality inspection agencies, entrust them to conduct on-site inspection of supplier’s factory (such as production equipment, quality control process) and issue factory inspection report.

Chapter 4,10 key dimensions of supplier reliability assessment (with verification methods)

After screening out potential suppliers through channels, it is necessary to deeply evaluate from 10 dimensions of“Qualification, product, capacity, cost, after-sales, supply chain, case, integrity, ecological adaptation and cross-border ability”.

4.1 certification: A“Hard threshold” for verification

Must Check Qualification: Business license (business scope includes“Intelligent positioning equipment production”, avoid pure trading company) , production license, ISO9001 quality system certification, industry required compliance certification (such as MFI, CE) ;

Verification methods: suppliers are required to provide scanned copies of qualification documents, and check the validity of the license on the“State Administration for market supervision”, “EU CE official website” and“Apple MFI official website”, commission a third party if necessary.

4.2 product quality: measured“Core performance”

Sample testing (key steps) :

Sampling 3-5 sets of samples, testing in practical application scenarios (such as connecting mobile phones to test ecological compatibility) ;

Environmental Testing: immersion (IP68 level 1.5 meters underwater immersion for 30 minutes) , drop (1.2 meters down to the concrete floor) , observe whether the equipment is working properly;

Battery life test: record the battery drain time according to the daily usage frequency (e. g. 10 times a day, 3 hours Bluetooth connection)

Compatibility test: Test the connection stability on different brands of mobile phones (Apple, Huawei, Xiaomi, Samsung) to confirm that there is no adaptation problem;

4.3 production capacity: ensure“Stable delivery”

Capacity checks:

Visit the factory: Look at the number of production lines, the percentage of automation equipment (such as SMT placement equipment, aging testing equipment) , warehouse inventory (to avoid“Zero inventory” foundries) , the number of employees (to determine the scale of production capacity) ;

Production capacity: Determine whether the monthly production capacity is greater than 1.2 times the purchase requirement (with a buffer)

Custom capacity: if there is custom demand, confirm the supplier custom production line scale (such as the number of shell injection molds, LOGO printing equipment) ;

4.4 cost rationality: reject the“Low price trap”

Price Analysis: compare quotations from 3-5 suppliers;

Total cost accounting: add“Unit price + freight + tariff + installation fee + 3 years maintenance fee + return cost”, choose the best total cost scheme, not the lowest unit price scheme;

4.5 after-sales service: guarantee“Long-term use”

After-sales terms and conditions:

Trouble shooting: determine how the product will be handled

Technical support: confirm whether to provide 24-hour online technical support (such as wechat, email, phone) ;

Firmware updates: whether to commit to long-term firmware updates (e. g. fix bugs, add new features) , whether the update method is convenient;

Technical Support Validation: Test the responsiveness of the vendor’s technical team (e.g. send API docking requests, APP custom queries, see if solutions are returned within 24 hours) .

4.6 supply chain stability: avoid the risk of disconnection

Raw Material Inventory: confirm that the core parts inventory can support 1-2 months of production, provide the recent raw material purchase documents as proof;

Supply Chain Contingency: ask if the supplier has an alternative (i. e. , another chip with the same performance) if the core component is out of stock, and if the alternative needs to be retested and certified.

4.7 client cases: reference to“Actual word-of-mouth”

Cross-border case focus: for export procurement, prefer to select suppliers with experience in target markets (such as Europe, the United States) , understand their customs clearance process, customs declaration capabilities.

4.8 integrity: identify“Potential risks”

Contract Integrity: confirm whether suppliers accept the“First sample after the single”(first test samples and then sign a lot contract) ;

Communication integrity: observe whether the supplier is withholding information.

4.9 ecological resilience: meeting special needs

If you need to connect with Apple Ecology: verify that the supplier is an Apple MFI licensee, provide an MFI license, test whether the sample is properly connected to Find My network, and whether there is an official Apple compatibility test report

For Android ecosystem adaptation: test samples to see if they support Google Find My Device, Samsung SmartThings, and will work with different versions of Android, such as Android 10 and above

Eco-compliance: ensure that the supplier’s products do not infringe the intellectual property rights of the ecological party (such as using unauthorized Find My agreements) , and avoid subsequent legal risks.

4.10 cross-border capabilities (export procurement scenarios)

Customs clearance experience: ask if the supplier has customs clearance experience in the target market, can provide commercial invoice, packing list, certification documents (such as CE, FCC-RRB- and other customs clearance information;

Logistics Cooperation: whether there is a long-term cooperation of cross-border logistics providers (such as DHL, FedEx, sea freight forwarders) , whether to provide door-to-door (DDP-RRB- services, reduce logistics costs;

Chapter 5, procurement negotiation and contract signing: locking in the“Boundary of power and responsibility”

After the final supplier has been identified through evaluation, subsequent disputes need to be avoided through professional negotiations and the regularization of contracts:

Key negotiating points

Price negotiation: use“Bulk purchase quantity” and“Long-term cooperation commitment” as bargaining chips to obtain discounts (e.g. , 10% unit price discount for purchasing more than 10,000 units, and an additional 5% discount for committing annual purchase quantity ≥50,000 units) , at the same time, ask for“When the follow-up purchase volume increases, the unit price will be reduced by 5% simultaneously”;

Customization Requirements: define customization content (e.g. LOGO, shell color, APP functionality) , development cycle (e.g. 20 days to complete APP customization) , additional costs (e.g. tooling cost sharing) and intellectual property ownership (e.g. copyright of customized APP belongs to the purchaser)

Delivery and logistics: clear delivery location (e. g. Ex works, warehouse delivery, door-to-door delivery) , logistics mode (air/sea/Land-RRB- , freight undertaker, customs duty undertaker for cross-border procurement;

Warranty and aftermarket: negotiate an extension of the warranty period (e.g. from 1 to 2 years) , a commitment to reduce the DOA rate (e.g. from 1% to 0.5%) , and an increase in the“Aftermarket response timeout”(e.g. 1% off the order amount per day if no response is received for more than 24 hours) .

Chapter 6, post-purchase: Cooperative Management and risk aversion

Bulk purchasing is not“The end of the contract signed”, through follow-up management to ensure the quality of long-term cooperation, reduce performance risks:

6.1 acceptance of the first batch (key node)

Acceptance Process:

Visual inspection: Check whether the packaging is intact, whether the product is damaged, whether the LOGO and LOGO are in line with the agreement, whether the accessories (such as charging cable, instructions) are complete;

Performance test: according to the contract parameters sampling test positioning accuracy, endurance, waterproof, ecological compatibility, record test data and signed by both sides;

Document check: ask for“Product certificate”, “Batch test report”, “Warranty card”, “Customs clearance documents (cross-border procurement)”, ensure complete;

Third-party sampling: for large orders (such as ≥100 million yuan) , can be entrusted to a third-party quality inspection agency sampling, sampling report issued;

Problem handling: if nonconforming product is found, immediately notify the supplier in writing, return or replace the product as required by the terms of the contract, and record the type of problem (e.g. inaccurate positioning, damaged casing) , follow-up procurement should focus on this type of problem.

6.2 establish regular communication mechanisms

Monthly Communication: Hold Monthly Video Conference with supplier interlocutors (E. G. Sales + Technology + after-sales) , give feedback on product usage (e. g. failure rate, battery life compliance rate, customer complaints) , iNFORM purchasing plan for next month (e.g. quantity, custom)

Quarterly Review: the two sides jointly evaluate the quarterly cooperation, from the“Delivery on time, quality, after-sales response speed, cost control” four dimensions score (100 points) , more than 80 points can consider increasing the amount of procurement, 60 points below the need to put forward rectification requirements (such as within 1 month to optimize after-sales process) ;

Annual cooperation evaluation: According to the annual cooperation score, decide whether to renew the“Annual framework agreement”, and negotiate the next year’s price discount, capacity guarantee, custom support and other terms;

Emergency communication mechanism: establish wechat/Telephone Emergency Contact Group, ensure to provide solution within 24 hours in case of disconnection and sudden quality problems.

6.3 supply chain risk management

Establish alternative suppliers: reserve 1-2 alternative suppliers (through Chapter 4 Evaluation Dimension Screening) , test their samples regularly (quarterly) , confirm the product performance is consistent with the main supplier, ensure that when the main supplier is out of supply, can switch suppliers within 7 days

Avoid“Single supplier dependence”: even if the main supplier performs well, it is necessary to allocate 30% of the purchase volume to alternative suppliers to reduce supply chain risk;

Inventory management: establish safety stock according to purchase cycle (e. g. 30 days delivery) and usage (e. g. 15 days usage) to avoid business disruption caused by supplier delivery delay;

6.4 after-sales problem handling and optimization

Failure record: establish“After-sales problem ledger”, record failure equipment number, problem type, processing time, solution, customer feedback, analysis of high frequency problems (such as a batch of equipment lack of battery life) , ask the supplier for corrective action

After-sales improvement: if the after-sales response is slow, the supplier is required to increase after-sales personnel;

Customer Feedback Collection: regularly collect end-user (e.g. corporate, consumer) feedback on locator usage, pass it on to suppliers, and drive product iterations (e.g. adding“Low battery alert”) .

Chapter 7: common purchasing mistakes and how to avoid them

7.1 mistake 1: Looking only at the unit price and ignoring the total cost

Case Study: in order to save cost, a cross-border e-commerce company selected a supplier with a unit price 20% lower, and then found that the equipment could not be exported to Europe without CE certification, so it had to re-purchase compliant products and spend an additional 500,000 yuan At the same time, the equipment endurance is only 50% of the commitment, the customer return rate is more than 30% , the loss of sales of 100 million yuan;

Avoid the pit: calculate the total cost of“Unit price + Freight + tariff + certification fee + after-sales cost + return loss”, and give priority to the supplier with the best total cost, rather than the supplier with the lowest unit price.

7.2 myth 2: Don’t test samples, buy in bulk

Case Study: a nursing home purchased 1000 sets of personnel locators in batches, but did not test the samples. After arrival, it was found that the indoor positioning accuracy was more than 10 meters (≤3 meters as agreed in the contract) , which could not meet the monitoring needs, return loss of 50,000 yuan (including freight) , and delay elderly care project for 2 months;

Avoid the pit: regardless of the reputation of the supplier, you need to purchase 3-5 samples and test them for 1-2 weeks in practical application scenarios (such as indoor test positioning accuracy, outdoor test GPS stability) , after verification, sign the batch contract; the samples should be signed by both parties and used as acceptance criteria.

7.3 myth 5: ecological compatibility is ignored, making the product unusable

Case Study: a consumer electronics manufacturer purchased 10,000 Bluetooth TAGS, failed to test Apple Find My compatibility, and upon arrival found that the device could not connect to the Find My network and could not be sold to Apple users, it had to sell them cheaply to Android users, losing $300,000

Avoid pit: if you need to connect to a specific ecosystem (e.g. Apple Find My, Google Find My Device) , focus on testing compatibility during the sample testing phase, and ask the supplier to provide ecological compatibility certification (e.g. MFI certificate) , and note in the contract that“Incompatibility is considered nonconformance”.

7.4 myth 6: cross-border procurement doesn’t focus on Customs clearance and tariffs

Case Study: an enterprise exporting 5000 locators to the United States failed to confirm whether the supplier had FCC certification. The goods were detained at customs and had to pay a fine of $20,000 and a one-month delay in re-certification, customers cancel orders, loss of $100,000

Avoid pit: before cross-border purchasing, confirm suppliers have target market certification (such as FCC, Europe CE) , require suppliers to provide customs clearance information (commercial invoice, packing list, certification documents) ; Understand target market tariff policy (e. g. EU VAT rate) and identify duty bearer in contract.

Chapter 8, summary: core characteristics of reliable suppliers and key procurement actions

8.18 characteristics of a reliable supplier

Qualifications: A Production License, ISO9001 certification, industry required compliance certification (such as MFI, CE) , no breach of trust records;

Excellent products: the sample test meets the demand, batch quality is stable (pass rate ≥99%) , ecological compatibility standard;

Capacity matching: monthly capacity ≥1.2 times of purchasing demand, can support customized demand, have spare capacity to deal with supply interruption;

Reasonable cost: the quotation is transparent, the total cost (including after-sales, tariffs) is competitive, no hidden costs;

After-sales improvement: warranty period ≥2 years, after-sales response ≤24 hours, timely troubleshooting (replacement within 7 days) , support long-term firmware update;

Supply chain stability: core components have 2-3 alternative suppliers, raw material inventory can support 1-2 months of production;

Case-rich: with the industry cooperation cases (such as the target market, similar procurement scale) , customer evaluation is good;

Cooperation in good faith: accept the“First sample after the single”, contract terms clear, no hidden information, take the initiative to assume responsibility for breach of contract.

8.2 key actions in purchasing (condensed version)

Clear Requirements: from the product type, performance, scale, budget, certification, after-sales 6 dimensions of combing the list of requirements, with detailed parameters;

Multi-channel selection: through the vertical platform, exhibition, official channels, peer recommendation to expand suppliers, reserve 5-8 candidate suppliers;

In-depth assessment: from the qualification, product, capacity, cost, after-sales and other 10 dimensions of assessment, the preferred choice of original factory, eco-certification, cross-border experience of suppliers;

Sample test: purchase 3-5 sets of samples, in the actual scene test 1-2 weeks, confirm the performance, compatibility, quality;

Specification Contract: the contract clear product parameters, acceptance criteria, quality assurance terms, liability for breach of contract, with a sample confirmation;

First acceptance: according to the 3% sample test, check the documents, unqualified immediately returned;

Long-term management: establish regular communication mechanism, reserve alternative suppliers, monitor supply chain risk and drive product optimization.

8.3 recommended tools

Supplier rating form (for quarterly evaluations) :

| Evaluation dimensions | Full marks | Scoring criteria | Actual score |

| Delivery on time | 20 | 20 points for 100% punctuality, 2 points for every day of delay | |

| Quality pass rate | 25 | ≥99% score 25 points, deduct 1 point for each 0.1% lower score | |

| After-sales response time | 20 | 20 points will be awarded for ≤24 hours and 5 points will be deducted for every 12 hours exceeded | |

| Reasonableness of the cost | 15 | 15 points for total cost 10% below industry average, 5 points for total cost above 10% | |

| Cooperation degree of cooperation | 20 | 20 points for active feedback and cooperation, 5-10 points for passive cooperation |

Sample Test record sheet: record sample number, test items (positioning accuracy, endurance, waterproof) , test data, whether qualified, problem description;

After-sales problem ledger: record malfunction equipment number, problem type, receiving time, processing time, solution, customer feedback.

Through the above process, enterprises can efficiently find a reliable intelligent locator label supplier, to achieve“Cost control, quality standards, supply stability, customer satisfaction” bulk procurement goals, at the same time, we can establish long-term cooperative supplier relationship to support the sustainable development of business.